GLASS BOTTLE LINES 30BPM TO 300BPM

PRODEB glass bottle lines have been in operation worldwide for more than 40 years. PRODEB has designed manufactured and installed more than 500 lines for various products. Carbonated soft drinks, juices, milk, wine alcohol, Champagne, Beer and other carbonated and non-carbonated beverages are commonly packaged in glass bottle lines.

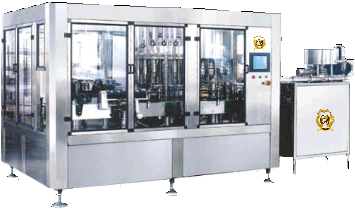

The Filler, Capper system incorporates various kinds of Filling valves as well as capping system. Gravity Filling valves, Hot Fill valves, Volumetric Filling valves and Counter Pressure Filling valves are some of the variants provided to package various products.

The capping system is also Flexible and designed to apply and seal various kinds of caps eg. Crown caps, ROPP caps, Twist off caps, and Tear off caps. The

system can be provided with cork capping for wine. The glass bottle system has a rated output from 30BPM to 600BPM in various models. It can handle bottles from 200ml upto 1000ml.

The system is produced with proven German Technology and has a extensive life of more than 25 years. The equipment is simple, rugged and operator friendly. Easy change over between bottles can be achieved in minimum time duration. The system comes with a Cleaning in Place (CIP) facility and a automatic lubrication system.

STANDARD FEATURES

- Production Flexibility: PET / Glass Bottle volume ranges from 60ml to 2 liters with special designs upto 3 liters. Segmented equipment design for future module Integration during up gradation.

- Highest food safety: All contact components in SS 304 / SS 316 / SS 316

- Infinite option of Filling valves to support innumerous product types.

- Maximum productivity : Drastically reduced change over and maintenance downtime.

- Simplified cleaning : CIP cleaning System for rapid and easy cleaning

- CIP System: A inbuilt CIP System for rapid closed loop cleaning ensuring reduced energy and chemical consumption

- Gravity Filling : High accuracy gravity Filling valves for consistent fill for Still liquids.

- Contact Less Filling : Volumetric contact less Filling ensures the most hygienic fill and its magnetic flow meter ensures accurate consistent fill volume in aseptic models. These valves are designed and built both for ambient temperature product fill as well as hot fill of 400C to 900C. The hot fill is mostly for milk, juices, ice tea and energy drinks. The ambient fill is for water and beverage.

- Counter Pressure Filling: Counter pressure Filling valves have been developed for sparkling water, carbonated beverages and beer. The counter pressure system ensures no foaming during and after fill. A specialized snifting system is provided to achieve the above.

- Hot Fill : Advanced hot fill valve are designed to fill hot products in the range of 40C to 800C. This is mostly for Juice, Milk, Ice Tea and Energy drinks.

- Cap disinfection by UV as well as ozonized water spray incorporated for maximum hygiene.

- Dry cap disinfection/sterilization with H2O2provided in *Aseptic Models.